prefabsshubhom@gmail.com

9654377793

prefabsshubhom@gmail.com

9654377793

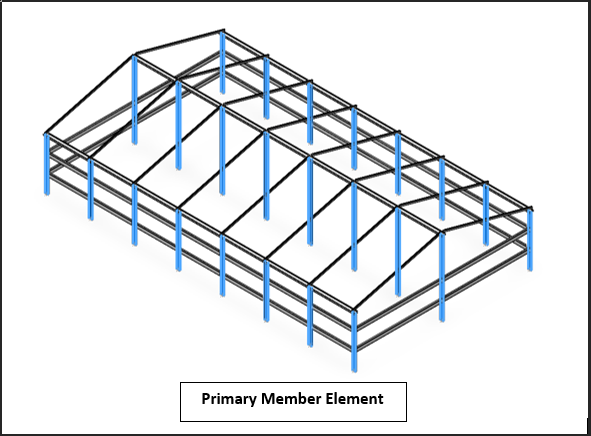

#Pre-Engineered Buildings concept specially known for economical design and compactness because they yield to strength and stability with minimal thickness. These are the structures basically produced at the factory with high tensile steel material by collecting complete information of the shed/building (viz; Length, Width, Height etc,). The entire design of column, rafters and other accessories is based on International structural standards and involve high technical welding and quality production. The entire requirement is produced on modular basis in house and shall be assembled at the customer's site with minimum time period and least cumbersome.

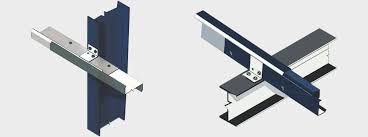

#Primary members consist of columns, rafters, beams etc. These are fabricated from high. Strength 354mpa plates. Plates are cut to size and shape. Built up sections are made from these plates in Automatic Beam welding Line by submerged Arc Welding..

#The most common primary framing systems are shown below. All are shown symmetrical about the ridge line. Framing systems un-symmetrical about the ridge line and Multi Span Framing Systems with unequal width modules are possible but may require more engineering time and possibly longer deliveries. Practically any frame geometry is possible. Consult an Sunrise representative for your specific requirements.

#PURLINSSecondary Members used in a PEB include purlins, side runners, eave struts, fascia channels; door posts window posts, rafter stays, column stays, base angles, and other miscellaneous structural parts. Purlins and grits are cold roll formed light gauge "Z" sections varying in depth from 180 to 300 mm and in thickness from 1.5 to 2.5 mm as per design requirement. The basic structural shape used by Sunrise, is given above.